Google uses cookies and data to:

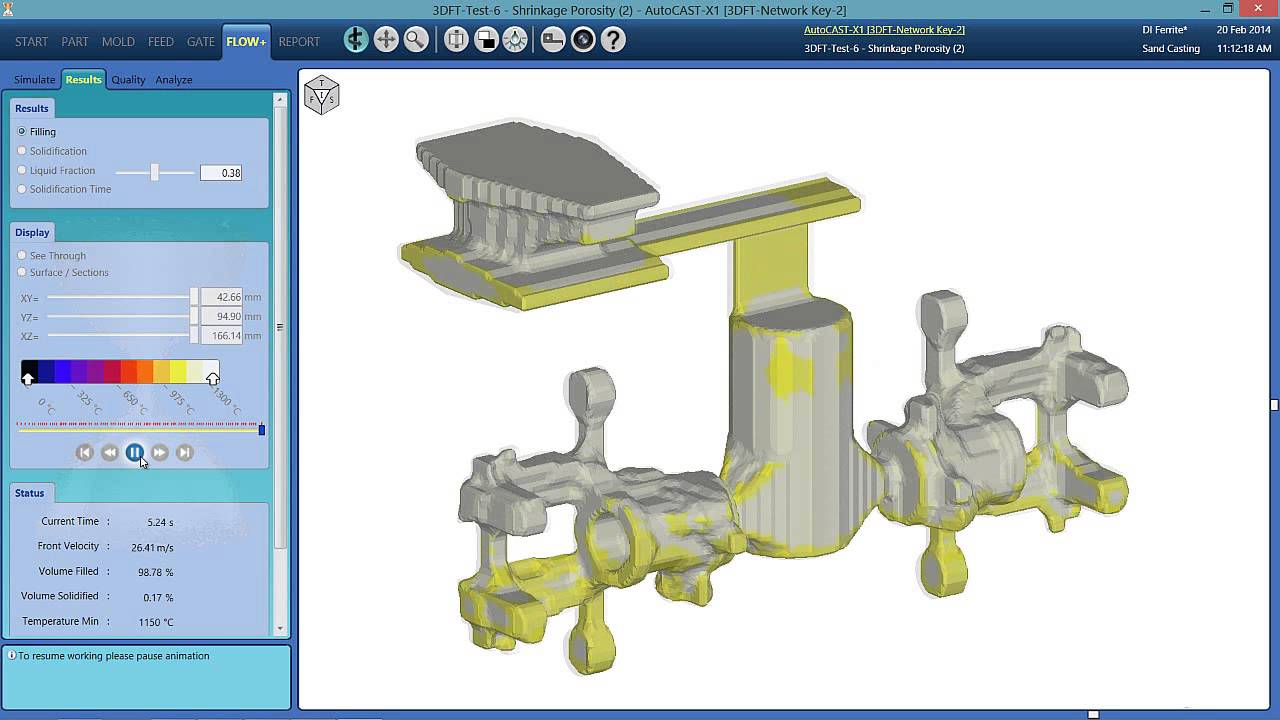

Simulation requires very less input data and gives reliable results which have impact on quality and yield. Separate design software is necessary to make CAD model as an input to simulation software. Simulation softwares accessible in India like ProCast, SolidCast, AutoCAST-X and MAGMA. Fig 10: Simulation chemical and gas content are examined. Warpage Simulation of Manhole Cover using AutoCAST-X Software. Quantitative Feeder Design for Metal Castings. Indigenous Development and Industrial Application of Metal Casting Simulation Software. Casting Design and Simulation of Cover Plate using AutoCAST-X Software for Defect Minimization with Experimental Validation. Autocast Simulation software, free download Bak Revolver X4 lasopamt. View credits, reviews, tracks and shop for the 1997 CD release of All Woman on Discogs. Autocast Simulation software, free download For Pc “AutoCAST is very helpful in new product development as development time is reduced. Casting yield is improved. Annual material saving is appox. Annual cost saving is appox. ” Rahul PatelTulip Castings Pvt Ltd. PERFECT SIMULATION PERFECT TECHNOLOGY. Warpage Simulation of Manhole Cover using AutoCAST-X Software. Quantitative Feeder Design for Metal Castings. Indigenous Development and Industrial Application of Metal Casting Simulation Software. Casting Design and Simulation of Cover Plate using AutoCAST-X Software for Defect Minimization with Experimental Validation.

- Deliver and maintain services, like tracking outages and protecting against spam, fraud, and abuse

- Measure audience engagement and site statistics to understand how our services are used

- Improve the quality of our services and develop new ones

- Deliver and measure the effectiveness of ads

- Show personalized content, depending on your settings

- Show personalized or generic ads, depending on your settings, on Google and across the web

Click “Customize” to review options, including controls to reject the use of cookies for personalization and information about browser-level controls to reject some or all cookies for other uses. You can also visit g.co/privacytools anytime.

Abstract:

The use of Aluminum castings parts in the automotive industry has increased dramatically over the past few decades. The driving force for this increased use is vehicle weight reduction for improved performance. In many cases the mechanical properties of the cast aluminum parts are superior to those of the cast iron or wrought steel parts being used.This paper proposes the computer simulation of the sand casting of Aluminum Plate. It aims to study the behavior of fluid flow during mould filling and solidification and to optimize the process parameters, which help to predict and control casting defects such as gas porosity and shrinkage porosity. Here an attempt is being made to model and simulate the casting process using the AutoCAST software. The technological as well as practical aspects of using casting software are illustrated with an industrial case study.

[1] RabindraBehera, Kayal. Sand Sutradhar. G, Solidification behavior and detection of Hotspots in Aluminum Alloy castings: Computer Aided Analysis and experimentalvalidation, International Journal of Applied Engineering Research, Dindigul, Vol. 1, No 4, (2011).

[2] Advanced Reasoning Technologies, AutoCAST software, http: /www. autocast. co. in, (2008).

[3] T.R. Vijayaram, S. Sulaiman, A.M.S. Hamouda, M.H.M. Ahmad, Numerical simulation of casting solidification in permanent metallic molds, Journal of Materials Processing Technology 29–33(2006).

DOI: 10.1016/j.jmatprotec.2005.09.025

Autocast Simulation Software Free Version

[4] R. W. Lewis, K. Ravindran, Finite element simulation of metal casting, International Journal for Numerical Methods in Engineering, Vol. 47, Issue 1-3, p.29–59, January (2000).

[5] S. Sulaiman, A.M.S. Hamouda,S. Abedin, M.R. Osman, Simulation of metal filling progress during the casting process, Journal of Materials Processing Technology, Vol. 100, Issues 1–3, No. 3, P. 224–229, April (2000).

DOI: 10.1016/s0924-0136(99)00409-4

[6] A. Venkatesana, V.M. Gopinathb, A. Rajaduraib, Simulation of casting solidification and its grain structure prediction using FEM, Journal of Materials Processing Technology, Vol. 168, Issue 1, P 10–15, September 15, (2005).

Autocast Simulation Software Free

DOI: 10.1016/j.jmatprotec.2004.09.090

Simulation software, free download

[7] Robert D. Pehlke, Computer simulation of solidification processes—The evolution of a technology, Metallurgical and Materials Transactions B, Vol. 33, pp.519-541, Number 4 (2002).

Autocast Simulation software, free downloads

DOI: 10.1007/s11663-002-0032-3